The Apex10 reloading press is the evolution of the Mark7 Evolution!

The Apex10 reloading press is the evolution of the Mark7 Evolution!

A new and greatly improved press, which builds on and adds to the success and unique features of its predecessor, the Evolution.

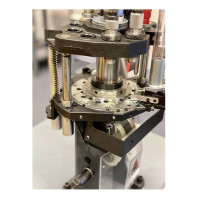

This amazing new press offers a massive 10 station tool head, which enables you to “do it all” in one pass.

The key differences and upgrades that the Apex10 offers when compared to the Evolution are as follows:

• A totally new case feeder includes these fantastic features:

• High speed output to easily keep up even when the press is automated and running at top speed

• The DC motor allows for variable speed adjustment

• A momentary Reverse button allows you to hit that button to instantly clear an output jam, if a case gets pinched and stuck at the exit hole

• A cutout window at the back of the collator lets you see how many cases are left, and also allows you to quickly open that window to empty out the collator when needed

• A hi-tech proximity sensor stops the motor when the tube is full

• A new rotary primer shuttle system replaces the slide bar, to feed the primers. Refined and improved. This system is ready to accept the new affordable Primer Xpress auto priming feeding solution, available soon.

• Parts for both Large and Small primers are included with every press, so no need to purchase primer conversion kits.

• The new tool head is cast iron for improved durability, and features dual guide rods as standard for additional stability and precision

• The core of the machine is upgraded to a cast iron chassis, which reduces the number of parts, bolts and assembly, making the machine more accessible for maintenance and easier to build and clean.

• A Lyman hold-down die is included as standard with every machine

Key Features:

• Upgradeable with Mark 7 Autodrives and sensors (compatible with Evo Autodrives)

• Ambidextrous Handle and smooth Ergonomic indexing

• Fully supported - Mark 7 community and technical help included

• Supports one-pass processing and loading thanks to its 10 stations and large tool head

• Precision CNC machined aluminum and steel

• Case feeder ready for mounting of a Mr.BulletFeeder

Comes Standard with:

• All new 11” High Speed Case Feeder

• Lyman Stainless Steel Pro Hold Down Die included

• Mechanical Powder Measure

• Standard Priming with all New Shuttle Disk Delivery System - Small/large primer conversion included

• Double Guide Rod support for the tool head creates more stability

A massive, robust 10-station cast iron tool head which allows you to “have it all”:

• Station 1: Case feeding

• Station 2: Sizing and decapping

• Station 3: Swage/Case trim

• Station 4: Primer seat with hold down

• Station 5: Case flare/neck expansion

• Station 6: Powder drop

• Station 7: Powder check

• Station 8: Bullet Dropper

• Station 9: Seating

• Station 10: Crimping

The above is just one possible set-up. The 10 station tool head offers a large variety of options for all your reloading and case processing needs

Upgradeability:

The Apex10 can easily be upgraded with the following options, at any point:

• Mark 7 Autodrive (compatible with the Evolution Autodrive)

• Mr.BulletFeeder by DAA

• Primer Express – Electronic Oscillating Primer System

• Digital Powder Measure (when combined with Autodrive)

• Digital Sensors (when combined with Autodrive). Same sensors as used on EVO.

• Machine caliber conversion kits that include everything required to convert the press from one caliber to another

• Trimmer kit for rifle processing

Please Note: A Hold-Down Die is included, but additional dies are not included with the Apex10 and must be purchased separately.

Dimensions: Press core dimensions are: 18” tall x 15” wide x 11” deep (45.7cm x 38.1cm x 27.9cm) Machine weight: 60lbs (27.3kg)