Mark 7 Evolution - Primer Orientation Sensor

While loading on a Mark 7® Evolution® or Revolution® you now have the ability to stop the machine if you have a primer that is missing or have other issues inserting a primer. Have you had the situation where you are loading at a pretty good pace only to find out that your supply contains non-conforming or missing primers? This can create havoc on your supply and loading operation–and in general–is a headache. Well, we have a solution !

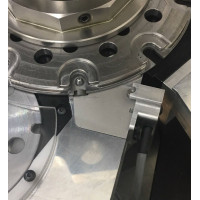

This sensor is only available for the Evolution® and Revolution® class of machines that have priming systems in them (not brass processors). Regardless if you're set-up in Stacked Priming or with the Onboard Primer Collator this sensor slides right into the cut-out near your primer punch.

There are two specific functions of this sensor:

How does it work? You set the level of the primer probe at the side of the sensor so that the indication level is custom to your needs. Cartridges slide across the probe and if they meet the level the you set, the machine will continue to operate and if not, the machine can stop. The indexing sensor component of this unit works independently and senses the shell plate rotation. The programming on the machine is designed to alert the user when the machine has made a stroke but the shell plate has not indexed, or rotated. This sensor helps increase the utility of your machines by streamlining the overall loading process.